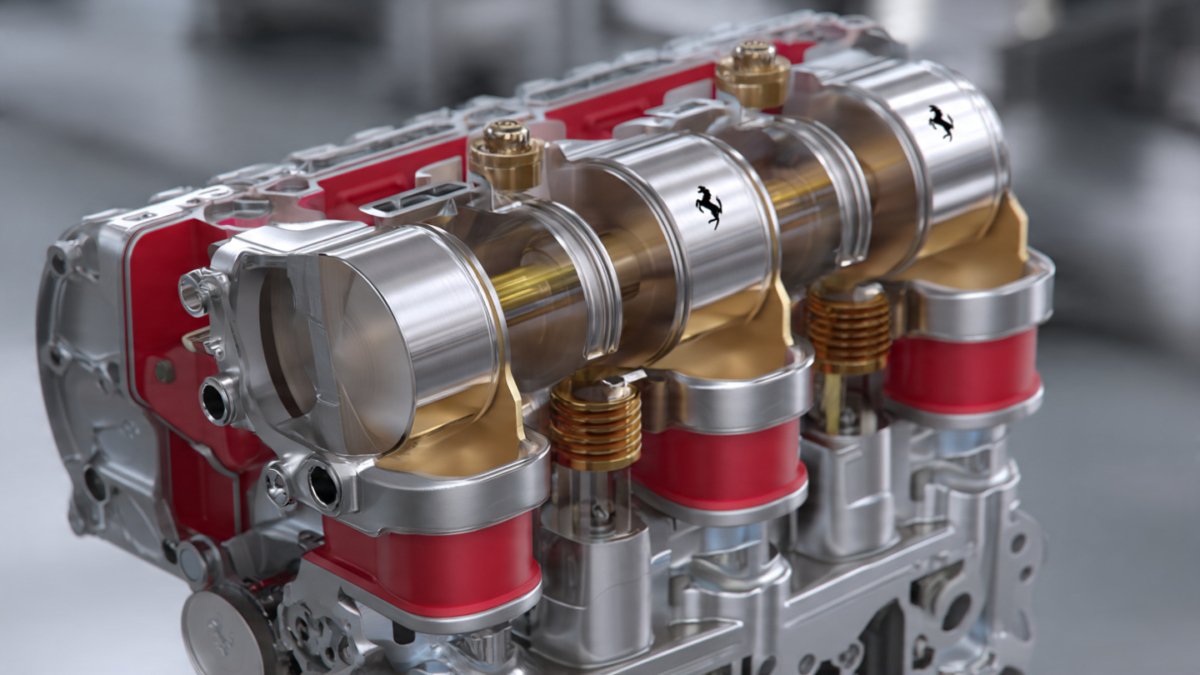

Ferrari, a name synonymous with high-performance automotive engineering, has once again captured global attention with a groundbreaking announcement. The company recently unveiled its new oblong piston technology—a radical departure from conventional cylindrical pistons—and claims that this unexpected redesign could transform engine performance, efficiency, and dynamics far beyond what current models achieve. This innovation promises to redefine internal combustion engines in ways that could ripple across the automotive industry for years to come.

The Basics of Piston Design

At the heart of every combustion engine lies the piston, a component that converts the energy of fuel combustion into mechanical motion. Traditionally, pistons are cylindrical in shape, moving up and down within engine cylinders to compress air and fuel, transfer force to the crankshaft, and ultimately generate motion. The geometry of pistons has been refined for over a century, with engineers focusing on materials, coatings, and tolerances to optimize performance, durability, and fuel efficiency.

Cylindrical pistons offer predictability and reliability. Their uniform shape allows for consistent sealing against cylinder walls, smooth motion, and well-understood thermal dynamics. However, even with decades of incremental improvements, cylindrical pistons have limitations in airflow dynamics, combustion efficiency, and friction management. Ferrari’s oblong piston concept seeks to address these challenges with an entirely new approach.

What Makes Oblong Pistons Different?

Unlike traditional round pistons, Ferrari’s oblong pistons feature an elongated, oval-like shape. This design is not merely cosmetic—it fundamentally changes how the piston interacts with the cylinder, air-fuel mixture, and combustion process. According to Ferrari engineers, the oblong geometry offers several performance advantages:

- Enhanced Combustion Efficiency

The oblong shape allows for a larger surface area at the top of the piston. This improves the combustion chamber’s airflow, promoting more complete fuel burn. Better combustion reduces wasted fuel, increases power output, and lowers emissions. Engineers report that the redesigned pistons optimize turbulence and flame propagation, ensuring more consistent and powerful combustion cycles. - Reduced Friction and Heat

The oblong piston’s unique contact points with the cylinder walls reduce surface friction compared to cylindrical pistons. Less friction means less heat generated, improving the engine’s thermal management. Lower operating temperatures reduce the risk of overheating and engine wear, contributing to longer lifespan and more reliable performance under extreme conditions. - Higher Torque and Power Potential

Ferrari’s simulations suggest that oblong pistons can generate higher torque across a wider RPM range. The elongated shape distributes pressure more evenly during combustion, reducing stress on individual piston sections. This allows the engine to maintain efficiency and power at higher speeds and under heavier loads. - Optimized Fuel-Air Mixture

The oblong design influences how the air-fuel mixture swirls within the combustion chamber. By controlling turbulence more precisely, the engine can maintain a more uniform mixture. This enhances throttle response and ensures that every combustion cycle contributes effectively to engine output.

Overcoming Engineering Challenges

Introducing oblong pistons is not a simple matter of swapping one shape for another. Engineers faced numerous technical challenges during the development process.

Cylinder Compatibility: Traditional engines are designed for round pistons, so oblong pistons require precisely engineered cylinder shapes or liners. Ferrari engineers developed proprietary machining techniques to ensure tight tolerances and uniform contact without compromising structural integrity.

Sealing Technology: Pistons rely on rings to seal against cylinder walls and prevent combustion gases from escaping. Oblong pistons required the redesign of piston rings to maintain consistent sealing throughout the piston’s elongated profile. Ferrari implemented advanced materials and coatings to minimize wear and maximize durability.

Stress Distribution: The new geometry alters force distribution inside the engine. Engineers conducted extensive simulations to ensure that stress does not concentrate in vulnerable areas, preventing premature failure and ensuring long-term reliability.

Manufacturing Precision: Producing oblong pistons demands ultra-precise machining and quality control. Even minor deviations in shape could compromise performance. Ferrari invested in advanced production techniques, including 5-axis CNC machining and laser surface treatments, to achieve the necessary tolerances.

The Impact on Engine Performance

Ferrari claims that engines equipped with oblong pistons could deliver unprecedented levels of performance. While exact specifications remain under wraps, early tests suggest potential benefits that extend far beyond traditional enhancements:

- Higher Horsepower: Engineers report that oblong pistons can increase peak horsepower by improving combustion efficiency. More fuel energy is converted into usable mechanical motion, translating directly into faster acceleration and higher top speeds.

- Improved Fuel Efficiency: With optimized combustion and reduced friction, engines consume less fuel while maintaining power. This is particularly important for meeting stricter environmental regulations without sacrificing performance.

- Smoother Power Delivery: Torque distribution is more uniform across the RPM range, offering smoother acceleration and improved drivability. Drivers may experience more responsive throttle behavior and reduced engine vibrations.

- Reduced Engine Stress: By distributing combustion forces more evenly, oblong pistons reduce localized stress on engine components, potentially extending engine life and lowering maintenance needs.

Broader Implications for the Automotive Industry

Ferrari’s oblong piston technology could have ramifications far beyond the company’s own supercars. If adopted widely, this innovation may reshape how engineers approach internal combustion engine design:

- High-Performance Vehicles: Sports cars and racing vehicles could achieve new benchmarks in acceleration, efficiency, and reliability. The ability to extract more power from smaller engines aligns with trends toward downsized, turbocharged powertrains.

- Sustainable Engineering: By improving fuel efficiency and lowering emissions, oblong pistons may help high-performance engines meet stricter environmental standards. This addresses a key challenge for automakers balancing performance and sustainability.

- Cross-Sector Applications: While Ferrari initially focuses on supercars, the principles behind oblong pistons could be adapted for industrial engines, marine applications, and even aviation, where efficiency and power density are critical.

Industry Reactions and Expert Opinions

Automotive engineers and analysts have expressed cautious excitement over Ferrari’s announcement. Dr. Luca Romano, a mechanical engineering expert specializing in internal combustion engines, commented:

“The oblong piston concept is fascinating. It challenges a century-old assumption that cylindrical pistons are optimal. If Ferrari can overcome the practical challenges of sealing and manufacturing, this could set a new benchmark for engine performance and efficiency.”

Other industry observers note that while oblong pistons show promise, long-term reliability and cost-effectiveness will determine their success. Manufacturing complexity and compatibility with existing engine architectures may limit widespread adoption initially.

Potential Challenges Ahead

Despite its promise, oblong piston technology is not without potential hurdles:

- Cost and Production Complexity: Developing engines with oblong pistons requires advanced machining and testing, which could drive up production costs. Initially, this may restrict the technology to premium or high-performance models.

- Aftermarket and Maintenance: Replacement parts and servicing protocols will need adaptation. Mechanics must be trained to handle the unique geometry and sealing requirements.

- Integration with Turbocharging and Hybrid Systems: Combining oblong pistons with forced induction or hybrid setups could introduce additional engineering complexities, although Ferrari engineers are reportedly exploring these possibilities.

The Road Ahead

Ferrari plans to integrate oblong pistons into its next-generation engines, with prototypes already undergoing testing on test tracks and simulation environments. While no commercial release date has been confirmed, the company hints that future supercars could showcase this technology, offering unprecedented performance and efficiency.

The unveiling also signals Ferrari’s commitment to pushing the boundaries of engineering innovation. In an era where electric vehicles are gaining traction, the company is demonstrating that internal combustion technology still has untapped potential when approached creatively.

Conclusion

Ferrari’s new oblong piston technology represents a bold and innovative step forward in engine design. By rethinking one of the most fundamental components of the internal combustion engine, Ferrari engineers are unlocking potential benefits in power, efficiency, and performance that could redefine automotive standards.

This unexpected redesign challenges long-held assumptions about piston geometry and highlights the potential for creative engineering to revolutionize even the most mature technologies. While practical hurdles remain, including manufacturing complexity and maintenance considerations, the oblong piston offers a glimpse into a future where internal combustion engines are more efficient, powerful, and responsive than ever before.

As Ferrari continues testing and refining this technology, automotive enthusiasts and engineers alike will be watching closely. If successful, oblong pistons could not only enhance Ferrari’s supercars but also influence engine design across the industry, demonstrating that innovation often comes from reimagining even the most established concepts.

Leave A Comment